Today we are talking about buy second hand machinery, Buying used industrial equipment can be a wise financial decision that allows you to save a lot of money while still getting the machinery you need. But to make sure you’re making a smart buy, navigating the market for used industrial gear need for knowledge and careful thought. Here are ten important recommendations to guide you through the process of buying second-hand industrial equipment, ensuring you get the best value and performance.

1. Understand Your Requirements at the topic of Buy Second Hand Machinery

To buy second hand machinery, Before going into the marketplace, it’s vital to have a clear grasp of your individual needs. What functions will the machinery carry out? What features are essential? Knowing what you need can help you choose the appropriate equipment and prevent you from paying more for features you don’t require.

2. Research and Compare

Investigate after you’ve determined what you need. Compare different brands, models, and their attributes. Look for reviews and feedback from other users to get a sense of the equipment’s reliability and performance. This stage is crucial in making an informed selection.

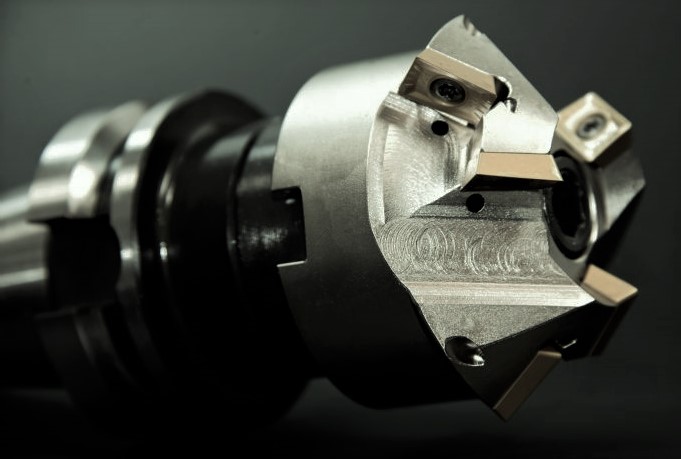

3. Inspect the Equipment Thoroughly at the topic of Buy Second Hand Machinery

When contemplating second-hand machinery, a thorough inspection is necessary. Check for wear and tear, rust, and any evidence of repair. If possible, operate the machine to confirm it functions correctly. Don’t hesitate to bring along an expert or a competent colleague to help with the inspection.

4. Inquire About the Equipment’s History

Understanding the history of the equipment can provide useful information about its condition and possible longevity. Ask about its previous applications, maintenance records, and any past repairs or difficulties. This information might help you judge how well the equipment has been maintained for and what kind of service life you might expect.

5. Take into Account the Seller’s Image at the topic of Buy Second Hand Machinery

To buy second hand machinery, It’s crucial to take their reputation into account whether you’re purchasing from a private seller or a dealer. Look for reviews or ask for references to confirm they’re competent and trustworthy. A reputable seller should be clear about the equipment’s condition and history.

6. Check for Warranties or Guarantees

While To buy second hand machinery frequently comes without the warranties given with new purchases, certain sellers could offer limited guarantees or return policies. These might provide an added layer of security and peace of mind in your investment.

7. Factor in Additional Costs at the topic of Buy Second Hand Machinery

Think about any additional expenses related to the equipment beyond the purchase price. This can involve transportation, installation, necessary repairs, or upgrades. To prevent any unpleasant surprises, be sure to account for these in your overall budget.

8. Evaluate Spare Part Availability

To buy second hand machinery, Make sure the equipment’s spare parts are easily accessible and up to date. The initial savings of purchasing used goods might be undermined by difficulties locating parts, which can result in more downtime and greater maintenance expenses.

9. Negotiate the Price at the topic of Buy Second Hand Machinery

To buy second hand machinery, Don’t hesitate to haggle the price. Second-hand markets sometimes provide greater area for negotiation compared to new equipment transactions. Armed with your research and the equipment’s inspection results, you’re in a great position to negotiate a reasonable price.

10. Plan for Future Needs at the topic of Buy Second Hand Machinery

To buy second hand machinery, Even while your present demands come first, think about how the equipment might fit into your long-term goals. Will it be upgradeable or flexible enough to accommodate future changes in your company? The equipment’s worth to your operations will increase if it can expand to meet your needs.

Conclusion

To buy second hand machinery, Buying second-hand industrial equipment is a clever strategy to stretch your budget while fulfilling your operating needs. By following these ten suggestions, you may traverse the market confidently, making educated selections that lead to successful and cost-effective acquisitions. Recall that the objective is to maximize your investment in the world of used industrial equipment by locating machinery that not only satisfies your present needs but also provides dependability and longevity.

Leave a comment