Glass ampoules play a crucial role in the pharmaceutical industry, serving as a preferred packaging option for certain medications. These small, sealed vials are designed to contain a single dose of a drug in a sterile and airtight environment. Several medications are commonly packaged in glass ampoules, and understanding their significance sheds light on the pharmaceutical packaging landscape.

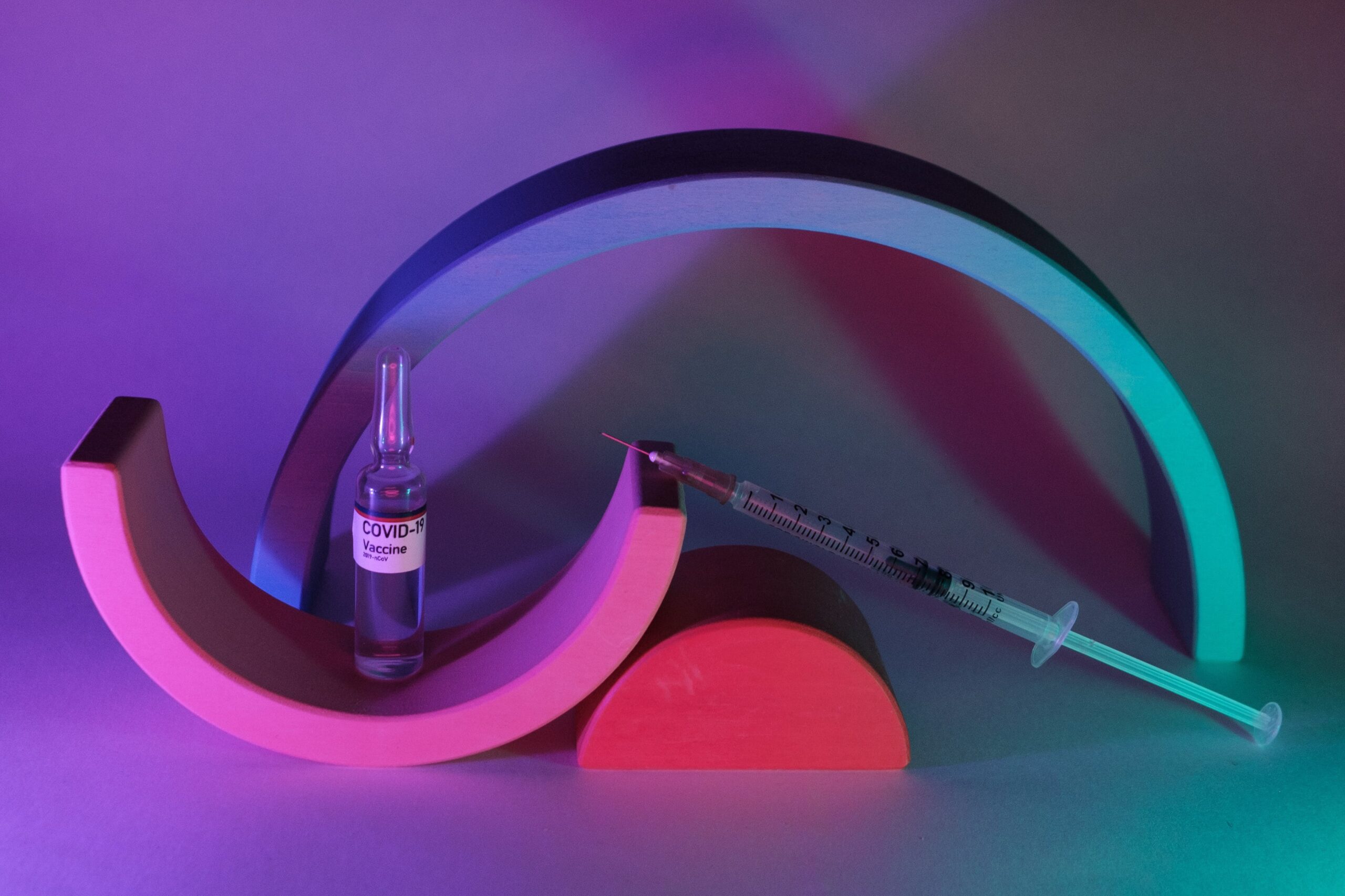

One notable category of medications often found in glass ampoules is injectable drugs. These include antibiotics, vaccines, and various types of injectable therapies. The use of glass ampoules ensures the stability and integrity of the medication, protecting it from external contaminants and preserving its efficacy.

Additionally, certain vitamins and minerals are also packaged in glass ampoules. This method of packaging helps maintain the potency of these sensitive compounds, safeguarding their effectiveness until the moment of use. Vitamins such as vitamin B12 and vitamin C, which may be administered via injection, are examples of medications commonly enclosed in glass ampoules.

Moreover, glass ampoules are favored for medications that require precise dosing. The sealed nature of ampoules allows for accurate measurement and administration of the prescribed amount, reducing the risk of dosage errors. This is particularly crucial for medications with narrow therapeutic windows or those where precise dosing is imperative for therapeutic success.

Glass ampoules also find application in packaging certain emergency medications, such as epinephrine. The breakable neck of the ampoule allows for quick and easy access to the medication in urgent situations. This characteristic makes glass ampoules a suitable choice for drugs that may need to be administered rapidly, especially in critical medical scenarios.

As pharmaceutical manufacturers strive for quality and efficiency, the process of producing glass ampoules has evolved. Glass ampoule making machines play a pivotal role in this evolution, facilitating the efficient and precise production of these specialized containers. These machines ensure the uniformity and sterility of each ampoule, meeting the stringent requirements of pharmaceutical standards.

In conclusion, glass ampoules serve as a reliable and effective packaging solution for a range of medications, particularly those requiring sterile and precise delivery. Their use extends to various therapeutic areas, including injectables, vitamins, and emergency medications. As the pharmaceutical industry continues to advance, the integration of glass ampoule making machines enhances the manufacturing process, ensuring the consistent production of these essential containers for medical use.

The pharmaceutical industry’s reliance on glass ampoules stems from several key advantages offered by this form of packaging. One notable benefit is the inert nature of glass, which ensures that the medication remains uncontaminated and unaffected by the container material. Glass is impermeable to gases and moisture, providing an ideal barrier to maintain the stability and potency of the enclosed medication over time.

Furthermore, the hermetic seal of glass ampoules enhances the shelf life of pharmaceutical products. The airtight enclosure prevents oxidation and degradation of sensitive drugs, contributing to the longevity of the medication. This feature is especially critical for medications that are stored for an extended period before use.

In addition to their protective qualities, glass ampoules contribute to sustainability in pharmaceutical packaging. Glass is highly recyclable, supporting environmentally conscious practices in the industry. The recyclability of glass aligns with the growing emphasis on reducing the environmental impact of pharmaceutical packaging, making glass ampoules an eco-friendly choice.

Glass ampoules are also preferred for medications with stringent sterility requirements. The manufacturing process of glass ampoules involves high-temperature sterilization, ensuring that each container is free from microorganisms. This level of sterility is crucial for injectable medications, where any contamination could pose serious risks to patient safety.

The use of glass ampoules extends beyond traditional pharmaceuticals to encompass various diagnostic and laboratory reagents. Their suitability for containing precise volumes of liquid makes them valuable in laboratory settings where accurate measurements are paramount.

As technology continues to advance, innovations in glass ampoule design are emerging. Some glass ampoules now incorporate features like tamper-evident necks, ensuring the integrity of the medication until the point of administration. These advancements address concerns related to product safety and help build trust among healthcare professionals and patients.

In conclusion, the role of glass ampoules in pharmaceutical packaging is multifaceted. Their ability to provide a secure, inert, and sterile environment for medications makes them a preferred choice for various therapeutic applications. With the integration of cutting-edge glass ampoule making machines, the pharmaceutical industry continues to benefit from improved efficiency and quality in the production of these essential containers, contributing to the overall advancement of healthcare delivery.

Leave a comment