You know how inconvenient sewage, drainage, or water pipe issues are? Maybe you have ever had them in your home or business. Even though they might not seem serious, problems caused by broken pipes can be costly and inconvenient. Specialised solutions are needed to fix your damaged plumbing pipes, and pipe relining is one of the finest options because it’s quick, low-risk, and frequently far more affordable than alternative remedies.

If you’ve noticed leaks and cracks in your pipes but would prefer to minimise the cost and any harm from digging them up, there might be a relining technique that can accurately resolve the issue without requiring you to disrupt trees or other landscaping or take unnecessary risks.

What is a Pipe Relining?

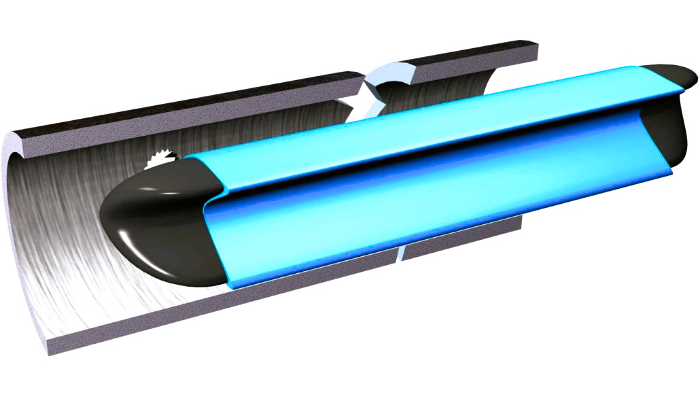

The term “pipe relining” refers to various techniques used to repair leaky and broken pipes inside instead of causing disturbance to the surrounding area through wall removal, floor demolition, trenching, and excavation. As the name implies, pipe relining in Geelong is the process of fixing or replacing a pipe’s interior surface, either with a coating, flexible tubing, or another rigid pipe.

The goal of all pipe relining techniques is to fix pipe issues with the least amount of disruption. However, which technique you use is crucial, particularly if you want your repairs to be as simple as possible.

How is Pipe Relining Done?

The procedure of relining pipes involves several steps:

Initial Pipe Inspection: To determine the degree and location of the damage, pipes are inspected. In the past, remotely operated cameras were utilised for this purpose, but with advancements in technology, a technique known as focused electron leak location, or FELL, is now employed to identify and assess the damage more precisely.

Pipe Cleaning:

- The pipes must first be cleaned.

- Any significant blockages must be removed.

- A high-pressure water jet must be used to clean the pipe to prepare the inner surface of the pipe wall completely for restoration.

This is done to guarantee that the product used to line the pipe will adhere well.

Secondary Pipe Inspection – Following the cleaning procedure, pipes are examined once again to confirm that the damage has been sufficiently cleaned and ready for relining and to determine the full amount of the damage. Usually, remotely operated closed-circuit cameras are used for this.

Determining Relining Length – Based on the total length of the pipe or pipes involved and the degree of damage, the pipe relining local plumbing group will establish how much the pipe needs replacing. If your pipe relining expert has multiple procedures available, they will assess which best fits the broken pipes and adjust the repair schedule accordingly.

Installing Pipe Relining Materials – The pipe relining specialist will perform the chosen relining procedure using one of the pipe relining techniques listed below. This could entail inserting and curing epoxy- or resin-coated tubing or a rigid polyethene replacement pipe in its stead. The curing process (if utilised) can take some time to harden properly, and any junctions or T-sections are more delicate and require more time and effort. Therefore, this part of the relining process takes the longest to finish. This process may also include cutting joints and access/inspection pits with grinders, robots, or surface-level cutters.

Final Pipe Inspection – The pipe relining expert will conduct the last checks and inspections after the relining procedure is finished to ensure all damage has been fixed and your pipes are operating as intended.

How Does Pipe Relining Work?

As previously said, various pipe relining in Geelong techniques are available (described below), and each can be applied to address particular problems that your pipes may encounter. Naturally, you can’t just pick one of these techniques at random; instead, you need to consider your unique situation and consult with suitably qualified experts, such as the staff at Green Planet Plumbing, who can advise you on the most effective technique for your pipe repair.

Widely Used Methods of Pipe Relining are

1. Cured in Place

Relining with cured-in-place pipe (CIPP) is one of the most used techniques. A felt tube saturated with resin, often composed of polyester or fibreglass, is put into the damaged pipe once it has been cleaned and allowed to dry. Hot steam jets cure the resin in situ, facilitating the felt’s adhesion to the pipe’s interior, allowing it to fill in internal fissures and solidify there.

2. Sliplining

Sliplining is an established, albeit rather antiquated, relining technique. The local plumbing group say sliplining process entails replacing a bigger damaged pipe with a smaller one by inserting the smaller pipe into it and grouting the area between them. Despite its effectiveness, this procedure lowers the pipe’s functional diameter, which may lead to obstructions in the future. Needless to mention, already tiny pipes cannot be used with this technique.

3. Pull-in-place Lining

Pull-in-place lining, as the name implies, is inserting a felt tube liner soaked in epoxy into the pipe using heat (such as steam) and then drawing the liner through the line until it covers the damaged area. After that, air is added to the pipe to expand the tube and maintain it in place while it dries by lining the walls of the damaged pipe. The inflated tube substitutes for the broken

pipe after it has dried.

4. Pipe Bursting

For severely damaged pipelines or sewer lines, pipe bursting is utilised. It is also best to utilise this procedure on outside subterranean pipelines due to its nature. Using a bursting tool on one end of the system that needs to be fixed is known as pipe bursting. With the use of hydraulics, this device disassembles the outdated pipe and pulls in fresh pipe to replace it.

5. Internal Pipe Coating

A great alternative for sewers and outdoor pipes is internal pipe coating. A thick layer of epoxy is then placed on the interior walls of the damaged pipes to conceal any damage once they have been fully drained and allowed to dry. The consequence of this epoxy coat is a robust internal coating on the pipe, which is allowed to dry for a few hours.

Find The Best Pipe Relining Solutions at Your Local Plumbing

Making an informed choice when choosing plumbing solutions requires knowledge of the various pipe relining techniques. Understanding these approaches allows experts and homeowners to manage pipe issues effectively, minimising interruption and extending the life of plumbing systems—whether they choose trenchless or cured-in-place pipe lining.

Leave a comment